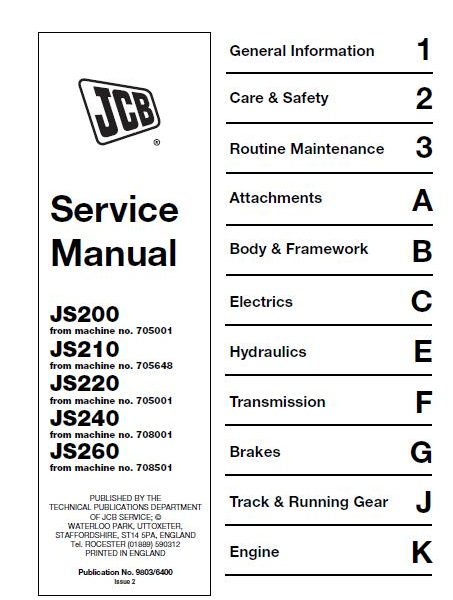

JCB AMS JS Machines Service Repair Workshop Manual Supplement. JCB JS70 Tracked Excavator Service Repair Workshop Manual. JCB JZ70 Tracked Excavator Service Repair Workshop Manual. JCB JS110, JS130, JS150LC Tracked Excavator Service Repair Workshop Manual. JCB JS115, JS130, JS130LC, JS145, JS160, JS180 Tracked Excavator Service Repair Manual. The first three sections of this manual are numbered and contain the following information: 1 General Information includes torque settings and service tools. 2 Care and Safety includes warnings and cautions pertinent to aspects of workshop procedures etc. 3 Maintenance includes service schedules and recommended lubricants for all the machine.

P0087 (flashing code 227) fuel rail pressure too low (for a pump without pressure applied)

Main symptoms

• Strong engine vibration.

• Unstable idling

• Output power drop

Exhaust smoke

• There may be too much smoke.

Js220 Jcb

P0088 (flashing code 118) fuel rail pressure too high

Main symptoms

• Strong engine vibration

• idle unstable

• Output power drop

• failure to pump the gas engine

Exhaust smoke

• May be too big a way out.

P0089 (flashing code 151) fuel rail pressure regulator faulty

Main symptoms

• Strong engine vibration

• idle unstable

• Output power drop

Exhaust smoke

• May be too big a way out.

P0090 (flashing code 247) SCV open or short of fuel pressure regulator

Main symptoms

• Depending on the open / short situations, the engine may stop and / or start

Exhaust smoke

• Smoke output too large

P0107 (flashing code 71) Atmospheric pressure sensor input signal low (open or shorted to ground)

Main symptoms

Due to a spare equivalent height of 2000 m (6562 ft)

• exhaust smoke at high altitude.

• insufficient power at low altitude

P0108 (flashing code 71) Atmospheric pressure sensor input high (+ 5 V short-circuited)

Main symptoms

Due to a spare equivalent height of 2000 m (6562 ft)

• High exhaust smoke

• lack of power at low altitude

The JCB JS240 excavator is the 24 tonne model in our heavy tracked excavators range. It’s engineered with exceptional strength, productivity, efficiency, comfort, safety and ease of maintenance.

A closed box section revolving frame increases strength and reduces stress. It also makes these excavators highly resistant to impact damage. We’ve used strong parts too – premium industry standards in fact.

Meanwhile, this 24tonne excavator’s engine is a highly efficient Isuzu 147 kW 4HK unit, compliant engine. It provides a fuel saving of up to 10% over our outgoing models. The benefits of the JS240 series of tracked excavators don’t end there either.

For more information on the JS240LC 24 tonne tracked excavator please contact your local dealer or call 1300 522 232.

QUICK SPECS

Watch Video

Jcb Js 240 Manual Transmission

SERVICEABILITYWe’ve designed JCB JS240 tracked excavators to be low maintenance and easily serviceable. Which makes them affordable, efficient and highly productive.

Bonnets open and close easily with gas-assisted cylinders, and the service bays are large and wide for good access. 1000-hour boom and dipper greasing intervals and a 5000-hour oil life provide maximum uptime on these 360 excavators. Grease points are centralised on a JS240 24 tonne excavator too, for safe and easy access to high level pivots. Likewise filters (engine oil, hydraulic oil and fuel).

Because they’re mounted side by side, the JS240 tracked excavator’s engine radiator, hydraulic cooler and intercooler can be serviced individually and cleaned easily.

STRENGTHBefore you buy tracked excavators, you need to know they’re going to be tough enough to perform any job you ask of them. Fortunately, with a JCB JS240 excavator, strength and durability come as standard.

We use Finite Element Analysis with extensive rig and endurance testing to make these 360 excavators last longer. A JCB JS240’s reinforced boom and dipper is made of high tensile strength steel, with single piecewrapper plates and internal baffle plates for long life durability.

The high-strength undercarriage of a JS240 24 tonne excavator is of a fully-welded X-frame construction for long-term durability even in the most demanding applications, and the rigid upper frame provides maximum durability and support.

The turret on JS240 tracked excavators is then welded to both the upper and lower undercarriage frames, and stiff, durable doors provide further strength.

OPERATOR COMFORT AND SAFETYWe’ve designed JCBJS240 tracked excavators to be comfortable, safe, ergonomic, simple and intuitive to operate. Which is good for operators of 360 excavators but even better for you; after all, great ease of use equals great productivity.

Cushioned boom and dipperends prevent shock loadings, protect your machine and increase operator comfort, while 6 viscous rubber mounts minimise noise and vibration.

A 70/30 front screen split for a clear view of the front right track, plus a large laminated glass roof window provide this 24 tonne excavator with exceptional all-round visibility

Jcb Js 240 Manual Pdf

To keep everything under control, JCB JS240 tracked excavators have a balanced slew and electronic/hydraulic controlled slew braking. Function switches are easy to reach and include the heater and climate control panels, while the sideunit doubles as part of the immobiliser code selector.

PRODUCTIVITYIt’s more important than ever to save money and time so it’s just as well that JCB JS240 tracked excavators are designed to make the most of both.

A massive 192kn bucket tearout makes our JS240 360 excavators up to 15% more productive than the closestcompetitors. Better still, a dipper tearout of 179 kN is up to 39% greater than the competition. The special JS range quickhitch system makes attachment changing fast and easy.

Simultaneous tracking and excavating is smooth and fast with an intuitive multifunction operation, and four operating work modes allow a JS240 excavator operator to tailor performance to any application. Auto, Economy, Precision and Lifting modes provide very different optimised settings.

Features

Jcb Js 240 Manual Diagram

- Up to 39% better dipper tearout than competitors

- Up to 15% better bucket tearout than competitors

- Class leading maintenance access

- Robust, durable upper structure and doors

- Spacious, comfortable cab design with excellent visibility

Jcb Js 220 Lc Excavator

Downloads

PLEASE FILL IN YOUR DETAILS TO DOWNLOAD